This boat is for my wife, and she wanted the seats dyed. She picked a "Vintage Cherry" from General Finishes. They look great. I dyed them a couple weeks ago and have since added two coats of epoxy to all of them, sanding between coats. They're ready for varnishing.

Today I installed them, but I'm doing it in a few steps instead of all in one shot as the manual says to do. I am first just tacking them down and using weights to keep them in place. Tomorrow I will sand those "spot welds" and then run nicer looking seams. The weights will be out of the way by then and it will be easier to make the seams without the seats moving.

For the thwarts, I first sanded a line down the middle of the underside of the thwarts so that epoxy would stick well, and then also lightly sanded the top of the bulkhead too. A small bead of thickened epoxy was added to the top of the bulkhead and then the seats were set down on top. When cured, it will be much easier to then add the remaining fillets to the thwarts.

PRO TIP: The manual doesn't mention this, but for the two thwarts, it is super important to have them in plane to each other so that the Piantedosi Drop-In Rowing Unit can sit evenly and distribute weight properly. I used a 4' level as a straight edge with bricks adding a bit of weight to keep the thwarts down on the bulkhead.

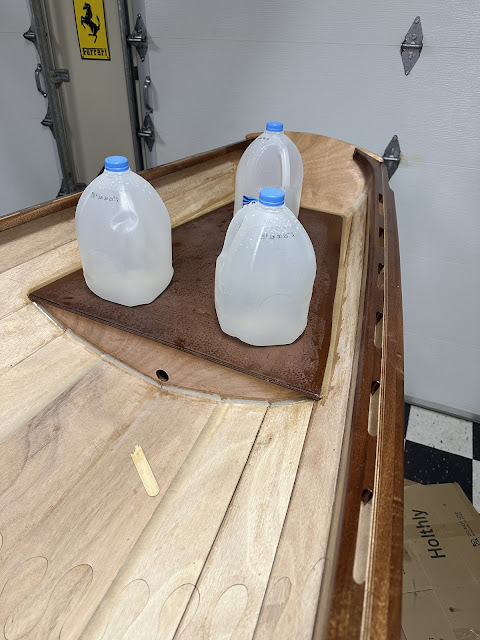

Here's the bow with the water jugs holding it in place while it cures.

The aft seat has a small fillet running all the way around it, but will get a more finished fillets once cured.

It's a bit hard to see in the picture below, but I didn't run the seams all the way yet for the forward seat. I used thickened epoxy at the top of the bulkhead, at the bow, and then in a couple of spots between the bow and bulkhead. This will firmly hold the seat in place and when cured will be much easier to run the full fillets.

Stay tuned!!

Comments

Post a Comment